Table of contents:

Why Chemical Plants Rely on Stainless Steel Sintered Filter Cartridges

Filtration Demands in Food and Beverage Manufacturing

Applications in Petrochemical and Gas Processing

Why Chemical Plants Rely on Stainless Steel Sintered Filter Cartridges

Chemical plants operate under demanding conditions, processing highly corrosive substances, extreme temperatures, and varying pressures. Stainless steel filter cartridges, particularly sintered options, are integral to these operations due to their durability and resistance to chemical corrosion. They are used to ensure that chemical mixtures remain free of particulates, protecting sensitive equipment and maintaining product purity. Sintered filter cartridges have uniform pore sizes, providing precise filtration tailored to the chemical plant's unique needs. For example, in applications such as polyester production, where controlling particulates is crucial, stainless steel filter cartridges are invaluable. Their ability to withstand high temperatures and pressures while providing consistent filtration performance makes them an essential tool in chemical manufacturing. This reliability ensures that delicate and complex processes can proceed without interruptions, maintaining product quality and safety standards. Additionally, their exceptional resistance to wear and tear not only guarantees longevity but also minimizes the need for frequent replacements or repairs, resulting in reduced downtime and more cost-effective operation over time. This durability ultimately contributes to improved operational efficiency and lower maintenance expenses for manufacturers.

Filtration Demands in Food and Beverage Manufacturing

The food and beverage industry faces rigorous safety and sanitation requirements, demanding filtration systems that uphold strict hygiene standards. Stainless steel filter cartridges are widely used in this industry due to their easy-to-clean design, non-reactive properties, and high filtration efficiency. From filtering oils and syrups to ensuring water purity in beverage production, these cartridges play a pivotal role in maintaining product integrity. A significant application includes filtering beer, wine, or other beverages where clarity and removal of unwanted particles are key. Thanks to their robust construction and ability to handle backwashing, stainless steel cartridges can be reused after cleaning, reducing overall operational costs. Their ability to ensure uniform filtering without shedding material not only guarantees compliance with strict health and safety regulations but also significantly enhances the quality of the final product. This level of precision is vital in industries where contamination can have serious consequences, such as food production and processing. By maintaining consistency and purity throughout the filtration process, these systems help uphold the highest standards of food safety, ensuring consumers receive products that are safe, reliable, and of superior quality.

Applications in Petrochemical and Gas Processing

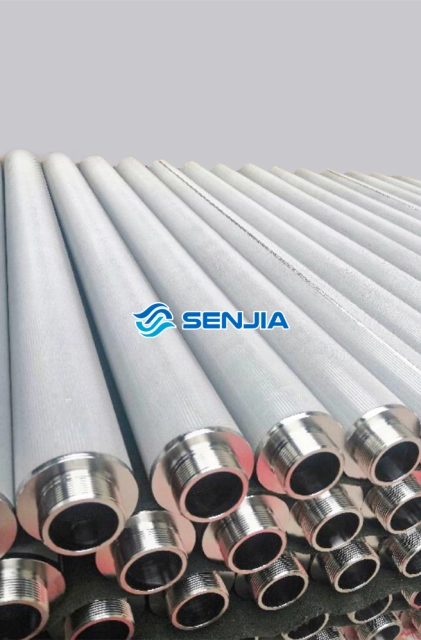

Petrochemical and gas processing industries are characterized by rigorous filtration demands to handle complex liquids and gas mixtures involving hydrocarbons, oils, and other substances. Stainless steel sintered filter cartridges shine in this domain due to their high precision and ability to operate under extreme conditions, including high pressures and temperatures. These cartridges help remove particulates and contaminants from gases and liquids, ensuring the safety and efficiency of downstream processing. Whether it is gas purification, removal of solid deposits in crude oil processing, or water treatment during refining, stainless steel cartridges provide consistent filtration performance. Their corrosion resistance and mechanical strength make them ideal for long-term use in harsh environments, reducing operational downtime and enhancing system reliability. Furthermore, their compatibility with custom connection systems, such as flange or threaded connections, ensures they can fit seamlessly into various setups, making them a preferred choice for filter cartridge manufacturers and users alike.

Stainless steel cartridges stand out as a durable, reliable, and versatile solution for a wide range of filtration needs. Their ability to withstand extreme conditions, provide consistent performance, and seamlessly integrate into diverse systems makes them a valuable asset across industries. By choosing stainless steel cartridges, users can achieve enhanced efficiency, reduced maintenance, and long-term cost savings, solidifying their position as a top-tier choice for filtration applications.

No comments:

Post a Comment