Table of contents:

Role of SS Filter Cartridges in Continuous-Flow Systems

Pressure Resistance and Flow Rate Optimization

How to Identify Clogging Before It Affects Production

Role of SS Filter Cartridges in Continuous-Flow Systems

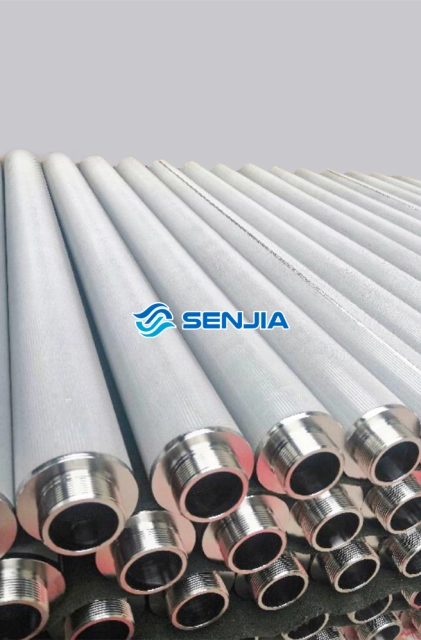

Stainless steel filter cartridges are integral to maintaining the seamless flow of liquids or gases in various industrial systems. They are engineered to sustain high-pressure environments and filter out impurities without compromising the flow rate. Unlike disposable elements, SS sintered filter cartridges have a long service life, offering excellent permeability and high corrosion resistance, even under extreme operating conditions. These features make stainless steel cartridges ideal for applications in industries such as water treatment, pharmaceuticals, petrochemicals, and food processing.For instance, in water treatment systems, these filters play a crucial role in maintaining consistent water quality, ensuring that the treated water meets the required standards without compromise. Unlike traditional filters, their durability and efficiency allow them to operate for extended periods without frequent replacements, significantly reducing downtime and operational disruptions. By partnering with a filter element store that specializes in high-grade stainless steel (SS) filters, you can ensure that you receive components specifically engineered to meet your unique operational requirements, enhancing both performance and reliability in the long term.

Pressure Resistance and Flow Rate Optimization

One of the standout features of stainless steel filter cartridges is their ability to withstand high pressures while ensuring consistent flow rates. This capability is achieved through advanced construction methods such as sintering, which binds multiple layers of stainless steel mesh to create a durable and uniform filtration medium. For industrial systems, maintaining an optimal flow rate is essential to prevent bottlenecks, overheating, or machinery strain. SS sintered filter cartridges manage this efficiently by offering precise filtration sizes ranging from 1 to 200 microns. This uniform filtration performance minimizes wear and tear on equipment, reducing the need for frequent repairs and associated downtime. Additionally, these cartridges are easy to clean and backwash, further enhancing their utility in high-pressure systems. Regular cleaning cycles can extend the product's lifespan, ensuring that your operations remain uninterrupted. Engineers and plant operators should consult with a filter cartridge manufacturer to choose filters that align with both their pressure requirements and desired flow rates.

How to Identify Clogging Before It Affects Production

Even the most reliable filter cartridges can clog if not properly monitored, leading to increased operational stress, reduced flow rates, and even unexpected shutdowns. To prevent these issues, it’s essential to implement effective strategies for early detection and maintenance. Monitoring pressure drops is a crucial step, as sudden changes in system pressure often signal a clogged filter. Regular maintenance schedules, including inspections and cleaning cycles, can further reduce the risk of buildup, with stainless steel filter cartridges offering the added benefit of easy backwashing for efficient upkeep. Visual inspections can also provide valuable insights if your system permits partial disassembly, allowing for the detection of visible debris or clogging signs. Additionally, partnering with trusted manufacturers, such as Senjia Filter, for customized solutions can enhance performance with features like anti-clogging coatings, optimized layer stacking, or tailored micron ratings to suit specific operational needs. By addressing potential clogging early, you can safeguard your system, minimize downtime, and ensure smooth production workflows.

Proactive maintenance and the use of high-quality, customized filtration solutions are essential to the longevity and efficiency of your systems. Identifying and addressing clogging issues before they escalate can prevent costly downtime and disruptions. By partnering with reliable manufacturers and implementing tailored filtration strategies, businesses can optimize their operations and maintain smooth, uninterrupted workflows.

No comments:

Post a Comment