Table of contents:

Innovative Applications of Flexible Conveyor Belts in Manufacturing

How Flexible Conveyor Systems Drive Industry 4.0

Embracing Technology: The Role of Flexible Conveyor Systems

Sustainable Manufacturing with Flexible Conveyor Solutions

Innovative Applications of Flexible Conveyor Belts in Manufacturing

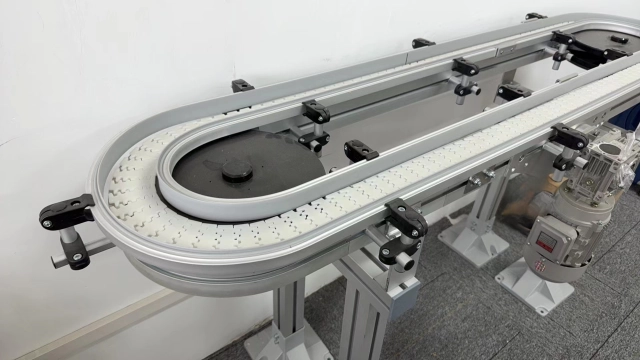

Flexible conveyor belts are transforming the way industries handle materials and products. These systems are not only versatile but also customizable, catering to the specific needs of various manufacturing sectors. As conveyor manufacturers continue to innovate, they are developing systems that can easily adapt to different environments and requirements. For instance, in the food industry, flexible conveyors made from materials resistant to acids, alkalis, and wear are crucial for maintaining hygiene standards. Additionally, their ease of assembly and maintenance makes them ideal for industries that require frequent changes in production lines. By leveraging the capabilities of these advanced systems, manufacturers can enhance their operational efficiency and reduce downtime.

How Flexible Conveyor Systems Drive Industry 4.0

The advent of Industry 4.0 has brought about a new era of smart manufacturing, where automation and data exchange are key. Flexible conveyor systems are integral to this transformation, providing the agility and precision needed in modern production environments. A conveyor system manufacturer like Juxin Automation offers solutions that integrate seamlessly with other automated technologies, facilitating a more connected and efficient production line. These systems enable real-time monitoring and control, allowing manufacturers to optimize their processes and improve overall productivity. As industries continue to embrace digitalization, the role of flexible conveyor systems becomes increasingly vital in driving innovation and competitiveness.

Embracing Technology: The Role of Flexible Conveyor Systems

As technology continues to advance, the manufacturing sector must adapt to remain competitive. Flexible conveyor systems play a crucial role in this evolution, offering manufacturers the tools they need to stay ahead. Conveyor manufacturers are constantly developing new features and capabilities to meet the changing demands of the industry. For example, Juxin Automation's systems are designed with high mechanical strength and excellent product handling performance, ensuring they can withstand the rigors of modern manufacturing. By embracing these technological advancements, manufacturers can improve their production processes, reduce costs, and enhance product quality, ultimately leading to greater customer satisfaction.

Sustainable Manufacturing with Flexible Conveyor Solutions

Sustainability is a growing concern for industries worldwide, and manufacturing is no exception. Flexible conveyor systems offer a sustainable solution by improving efficiency and reducing waste. As a leading conveyor system manufacturer, Juxin Automation emphasizes the importance of creating environmentally friendly products. Their systems are designed to be energy-efficient and durable, minimizing the environmental impact of manufacturing processes. By choosing flexible conveyor solutions, manufacturers can not only reduce their carbon footprint but also achieve cost savings through improved resource management. This commitment to sustainability is crucial for businesses looking to thrive in an increasingly eco-conscious market.

The integration of flexible conveyor systems into manufacturing processes is a game-changer for industries seeking to enhance efficiency and adaptability. As conveyor manufacturers like Juxin Automation continue to innovate, these systems will play an even more significant role in shaping the future of manufacturing. From driving Industry 4.0 to promoting sustainable practices, flexible conveyor systems offer a multitude of benefits that can help manufacturers stay competitive in a rapidly changing world.

No comments:

Post a Comment