Table of contents:

Leveraging Automatic Tube Filling Machines for Competitive Edge

Key Factors in Selecting a Tube Filling Machine Supplier

How Tube Filling and Sealing Machines Drive Industry Growth

The Future of Tube Filling Machine Manufacturing

Leveraging Automatic Tube Filling Machines for Competitive Edge

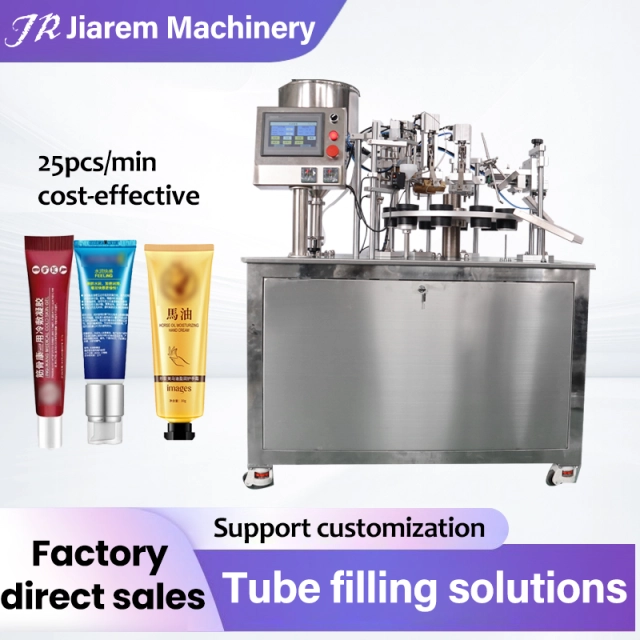

Automatic tube filling machines are revolutionizing the way industries handle their production processes. By incorporating these machines, a tube filling machine supplier can help businesses achieve faster production rates and higher precision levels. The machines operate at speeds of 10-30 units per minute and accommodate a filling range of 5-300ml, supporting tube diameters of 13-50mm and heights of 80-200mm. This versatility allows companies to cater to a variety of product specifications, enhancing their ability to meet diverse market demands. Moreover, features like automatic benchmarking and customizable production dates further streamline the manufacturing process, reducing the likelihood of errors and waste. As a result, businesses can enjoy increased productivity and reduced operational costs, solidifying their market position.

Key Factors in Selecting a Tube Filling Machine Supplier

Choosing the right tube filling machine supplier is critical for ensuring the success of your production operations. A reputable supplier should offer a comprehensive range of products and services, including customization options and rapid delivery. The experience and expertise of the supplier in the filling machine industry are also crucial factors to consider. A well-equipped factory with a large production capacity and a professional R&D team can provide the assurance of quality and innovation. Additionally, a reliable tube filling machine supplier should offer excellent after-sales support, including maintenance services and the option for door-to-door service. This ensures that any issues are promptly addressed, minimizing downtime and maintaining production efficiency.

How Tube Filling and Sealing Machines Drive Industry Growth

The integration of tube filling and sealing machines into production lines is a significant driver of industry growth. These machines not only enhance the efficiency and precision of manufacturing processes but also enable companies to expand their product offerings. By utilizing advanced features like internal heating for sealing and automated tail clamping and cutting, businesses can produce high-quality products with consistent results. This capability is particularly important in industries where product integrity and safety are paramount, such as pharmaceuticals and cosmetics. As companies continue to adopt these technologies, they can better meet the increasing consumer demand for diverse and high-quality products, thereby driving overall industry growth.

The Future of Tube Filling Machine Manufacturing

The future of tube filling machine manufacturing is poised for innovation and expansion. As technology continues to advance, manufacturers are likely to develop even more sophisticated machines that offer greater efficiency, precision, and versatility. The focus will be on creating machines that can handle a wider range of materials and product types, further enhancing the capabilities of industries that rely on these machines. Additionally, sustainability will play a key role in the evolution of tube filling machines, with manufacturers striving to create eco-friendly solutions that minimize waste and energy consumption. As a result, businesses partnering with a forward-thinking tube filling machine manufacturer will be well-positioned to capitalize on these advancements and maintain their competitive advantage in the market.

In summary, tube filling machines are an essential component of modern production operations, offering significant advantages in terms of efficiency, precision, and versatility. By selecting a reputable tube filling machine supplier, businesses can ensure they have access to high-quality equipment and support, enabling them to optimize their production processes and meet market demands effectively. As the industry continues to evolve, these machines will play a crucial role in driving growth and innovation, making them a strategic investment for any forward-thinking company.

No comments:

Post a Comment